Some misunderstandings about the assembly architecture

Just past 2016, the national policy level around the blowing frequency, follow up the implementation of the construction industry, the overall assembly showing a booming trend. It can be said that the building has risen to the national strategic level, everyone in the roll up your sleeves and go, the industry in the spring has come. However, there are still some misunderstandings and problems in the understanding of the assembly building.

First, is the assembly type structure, or assembly building?

At present, the promotion of the assembly building, is the product of the new building in the context of industrialization, are talking about the overall construction of the building changes, not just the main structure of the assembly problem. Therefore, the focus is on the industrial production, installation and management of building products, not just the main structure, which is the basic problem of the industrialization of the new building.

However, the reality is that the design and research of a large number of assembly buildings are still in accordance with the idea of assembly structure. There is a general emphasis on the main structure and neglect the misunderstanding of the whole building. Leading the development and design of the assembly building, the structure of the professional or stand on the structure of the majority. When discussing the assembly building technology system, it is also focused on the structural system, and even some of the main structure of the system of default for the assembly of the construction of the technical system.

In fact, for many years in the assembled steel structure construction experience has showed that the structure of engineers focus on the structural assembly model of prefabricated construction promotion is extremely unfavorable, especially prominent in residential. For born with steel structure assembly attributes, due to the lack of overall consideration of the building, is assembling building on steel structure, leading to the prefabricated construction blank Housing type large extensive, stagnant for years, missed promotion opportunities, and even affect the reputation of the prefabricated construction.

The newly published assembly building code, has been completely transferred to the assembly of the overall positioning of the building and ideas, to abandon the narrow concept of assembly structure. It is not difficult to see that the norms of the "assembly" is the "architectural" modifier.

Two, is the architectural design or construction system integration?

The traditional housing construction, divided into the architect LED professional split type of architectural design, and the construction of the unit led site construction, the two stages of separation. The construction of the assembled building is the process of the system integration based on the parts to realize the function of the building and meet the needs of the user. Therefore, we must use the product thinking, standing on the level of building systems integration, to think about the problem. However, the reality is that the implementation of assembly building, a large number of traditional ideas are still in use.

The characteristics of the assembly building, the need to break the traditional model of the first professional architectural design after the split, turn to the architect led, the integration of building systems, building products ideas. In other words, the architect is no longer a designer in the traditional sense, but an integration and product manager, led the design and integration of the product. Without the integration of product features and experience oriented thinking, can not do high-quality assembly building. On the basis of the traditional architectural function requirements, familiar with the various parts of the performance and integration of the building system integration technology, has become the core of the success or failure of assembly technology. Any problem that affects the function and experience of an integrated building product can lead to customer dissatisfaction. In fact, the problem of the quality of the attached building mostly occurs in the integration, integration and coordination between the main structure, the building envelope, the internal and the mechanical and electrical pipelines.

In this sense, the application of BIM technology is an important means to realize the integration of design, intelligent manufacturing, virtual assembly building architecture, can achieve the integration of prefabricated building process professional whole industry integration in a higher level, and not merely as a three-dimensional modeling tool. Using BIM technology to realize the LOD400 model of assembly building, it can be said that the system integration is realized.

Therefore, we must abandon the idea and practice of professional design, the design and construction of the traditional split apart, to see the prefabricated construction from the view of system integration, with the method of system engineering as the guide, taking BIM technology as a tool, the building functions as the core, the structural arrangement is based on industrial enclosure, interior and equipment the pipeline parts support, considering the building, apartment layout facade, structure system, retaining system, pipeline system, fire prevention, installed in all aspects of coordination and integration, the integration of system realization main structure system, peripheral equipment and pipeline system, and the system. Borrow Chinese engineering academy President Zhou Ji said, "integrated system decides success or failure, who in the world".

Three, is the standard design, or standardized design?

The assembly building follows the design concept of industrial production, the implementation of modular coordination and standardized design. However, the design of the assembly building is not the traditional sense of the standard design and stereotyped, but respect for personalized and diverse standardized design.

Standardization and diversification is a pair of contradictions inherent in assembly building. The architectural design is not equal to the diversification of liberalization, in the middle there is an individual standard, is the design requirements of standardization and diversity combining, based on standardized product component design done on the series, general. This contradiction is good or bad, is an important factor in the evaluation of assembly building, but also an important aspect of the assembly building technology system.

To achieve this goal, need to start from the top-level design, according to the characteristics of different types of buildings and parts components, combined with the functional demand, from the aspects of design, manufacturing, installation, maintenance, standard module of modular coordination and interface standardization of product components and structure, periphery and interior decoration the pipeline and equipment, the establishment of standardized technology system of modular, standard parts components and interfaces, and make the design, production, construction and acceptance of all included in the scope of coordinate dimensions, General Assembly building construction system. On this basis, the design of the building will be combined and integrated by standardized modules to form a variety of forms and effects, to achieve the purpose of diversification.

Therefore, the standardized design of assembly building is not equal to the single standard design, standardization is the method and process, diversity is the result, is inherent in the standard system flexible. In fact, Lego gives us some enlightenment, a large number of standard parts and a small number of non-standard parts, combined to form a variety of Lego architecture.

Four, is prefabricated make-up, or industrialization?

The embodiment of the assembled building is that the parts are manufactured and assembled in the factory. However, the assembly type building is not only a prefabricated assembly, but the way to achieve the construction of a new type of assembly building industrialization, the traditional construction industry is a major reference to the transformation and industrial restructuring. At present, it is easy to fall into the following misunderstanding.

1, prefabricated engineering, or prefabricated components?

At present, the general practice is actually the main structure of the prefabricated prefabricated, on-site assembly of ideas, the original site of the work of concrete transfer to the factory. So, the single project personalized design forced segmentation of prefabricated factory in fact has become the "factory prefabrication project", rather than "prefabricated components", from the structural components of modular and standardized intention. Indeed, some misunderstanding is due, there are also some enterprises, is in the current technology level to take mandatory prefabricated rate requirements of the last ditch.

This problem is particularly prominent in the assembly of concrete buildings. "Prefabricated project", led to process cost and logistics cost, engineering cost is much higher than that of the traditional cast-in-situ concrete building, even higher than the high price of the assembled steel structure building is generally believed that everyone in the subconscious, seriously affecting its popularization and application.

In addition, the assembly of shear wall is not necessarily the direction of advanced technology. For example, in Japan, in the past, the development process, has eliminated the slab structure of precast concrete system, only the precast concrete frame system.

2, assembly or construction industrialization?

At present, the assembly rate index is used to measure the level of industrialization in the process of assembly building. A lot of government regulations and incentives are designed for precast concrete. The common understanding is that it is possible to realize the industrialization of concrete by means of precast concrete and precast concrete. From the point of view of the project, most of the current is the traditional mode of production plus coat matching, is still extensive management, a lot of assembly and assembly. The main reason of the problem, is the understanding of the connotation of industrialization is not in place, still in development, the previous single industrial technology promotion and application level, is still limited in the general sense of the assembly building.

The construction of industrialization is a mode of production change, and assembling building is just one kind of building form and carrier, information management standard in the whole process of housing construction in the design, factory production, assembly of construction and the whole process is the main characteristic of industrial production, forming a complete industrial chain integration thus, to realize the socialization of production, not to generalize or replace the simple "assembly". The simple meaning of the construction industry to understand the assembly, and then to understand the assembly of prefabricated concrete, too narrow.

Five, the wall is buried pipeline, pipeline or separation SI system?

At present our country in the implementation of the prefabricated construction, the use of embedded in the wall structure and the pipeline in the traditional building practices. In fact, due to the pipeline and the structure, the different life of the wall, to the construction of the life cycle of the use and maintenance of the great difficulties.

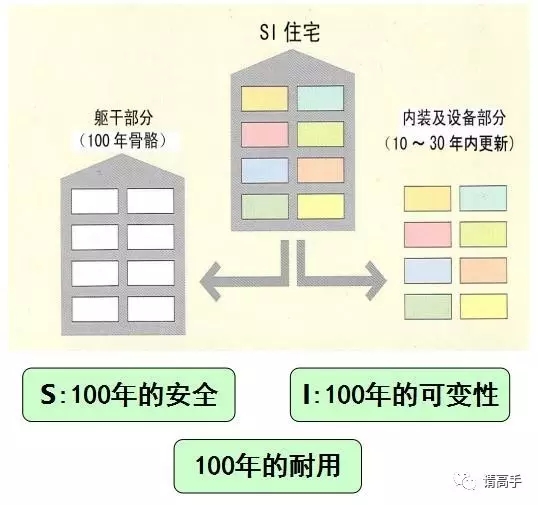

On this issue, the concept and practice of separating SI system from abroad should be popularized and applied. The so-called SI system is the support body S (Skeleton) and I (Infill) phase separation of the building system (mainly residential). Support refers to the construction of the framework, but not the same as the main structure that in the country, including the external and public wells can remain unchanged for a long part of the emphasis on durability; the filling body refers to filling the support body parts, including interior and internal pipeline equipment, strong flexibility and adaptability adjustment.

SI system from three aspects: one is to achieve the construction of long life completely separated from the supporting body, equipment and pipelines, built in three parts, to avoid the traditional inner buried pipeline practices in the wall and floor; two is to make the main structure more durable and durability design optimization; the realization of the three sets of flexible space and with high adaptability. The SI system has remarkable characteristics in improving the main structure and interior product performance, pipeline maintenance update, set room flexible three aspects, can guarantee the housing in the 70 years to 100 years of life which can be more easily installed in the renovation and parts replacement, so as to improve the quality of residential, residential extension the service life, reduce construction waste, to build a resource-saving society.

SI technology system has become the general system and development direction of international architectural industrialization. Buried pipe embedding structure wall is foreign, have been eliminated through practice. From this point of view, it is very important to build a new system of building industrialization based on SI technology.